We have a team of professional engineer for the product design with full design experience and skill.The desgined products have received big favor from our customers. The service includes Product design, mold-flow analysis and prototyping.

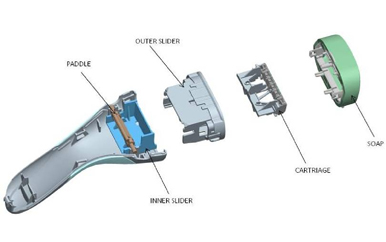

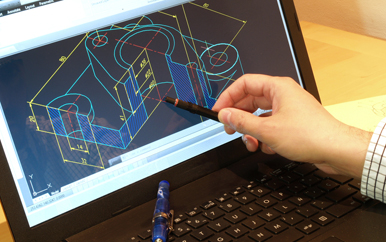

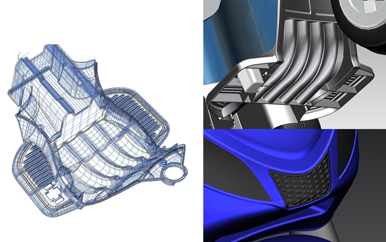

1.Product design

a. We can develop new products based on samples or prototypes by using reverse engineering,3D digitizing and laser scanning technology.

b. We can develop new products according to simple sketch and brief description like function.dimension etc.We provide customers with 3D model and 2D as request.

c. We can join in the customer’s design group. for example: summit the economic plan to save cost.point out the existing design problems for product such as the undercut.sharp angle .processing difficulty and so on.

|

|

|

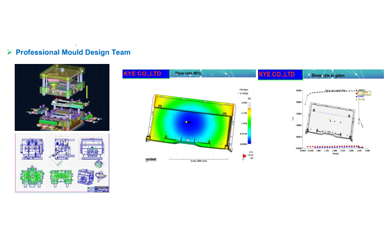

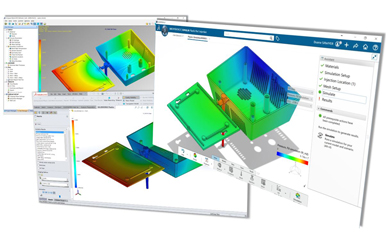

2.Mold-flow analysis

This is a very important process,because we need to understand the possibility of product in advance in order to prevent some possible problems like air trap.mark.and welding line etc. especially for the big product,so we introduce the advanced moldflow analysis software and professional engineers to stimulate ,analyze ,optimize and validate plastic parts and mold design .it effectively pre-prvent the potential problems as so to save cost ,control quality and guarantee delivery time.

|

|

.jpg) |

3.prototype-making

For some projects,Prototype is inenvitable process.it can help engineer check the product function and also prevent some problems which should be found after mould trial. In order to meet the requirement,we bought the advanced prototype equipment and cultivate the high-skill staff to do the prototype by CNC or laser machine . As a result ,it can help us provide customers with high-quality prototype for confirmation very fast.

4.Injection

It is ok to handle the injection from 80 tons up to 1600 tons:

Horinzonal injection machine

vertical injection machine

Double colour rotary machine

with air and robot assist injection machine

5.second –Processing

Spray painting

Pad printing and silkscreen printing

Engraving

Assembling