|

1.Mould standard |

DME |

|

2.Mould type |

2 plate-mould |

|

3.Mould base steel |

S50C |

|

4.A/B plate steel |

P20 |

|

5.Core/Caviry steel |

H13 |

|

6.Runner type |

Hot runner |

|

7.Gate type |

Pin gate |

|

8.Cycle time |

50s |

|

9.Design software |

CAD, UG, Proe |

|

10.MOQ |

1 set |

|

11.Payment term |

T/T |

|

12.Package |

Artificial wooden box |

|

13.Deliverly date |

5 Weeks |

|

14.Mould number |

According to customer requirement |

|

15.Mould life |

0.5 million shots |

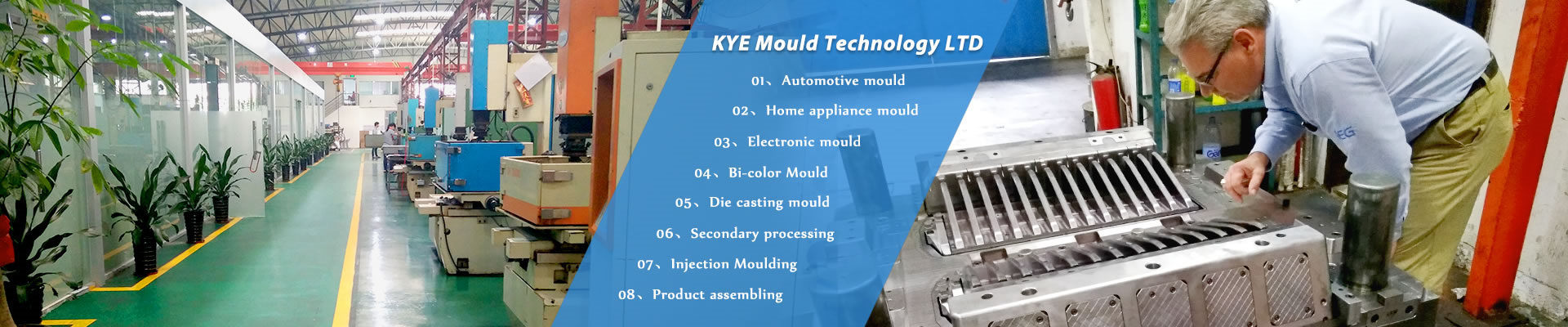

Welcome to KYE Mould Technology Limited